ENSURING AN AFFORDABLE ENERGY FUTURE

Using Plasma Energy To Turn Waste Into Value

News

-

National Science Foundation

RedShift Energy receives award from National Science Foundation for Carbon-Free Production of Hydrogen from Hydrogen Sulfide.

-

U.S. Department of Energy

RedShift Energy is now a U.S. Department of Energy Awardee.

-

Halliburton Labs

Halliburton Labs selects RedShift Energy for industrial scaling program.

About

RedShift Energy, Inc. is developing an innovative plasma process that dissociates hydrogen sulfide (H2S) into hydrogen and sulfur, with no carbon emissions. Conventional Claus-based Sulfur Recovery Systems do not recover hydrogen.

Thermodynamically, H2S is the least expensive source of carbon-free hydrogen when paired with renewable electricity. This novel process employs patented modular and scalable systems that retain their economic advantage from upstream to downstream. Deploying this disruptive technology will economically process H2S, while reducing emissions of carbon dioxide from Steam Methane Reforming hydrogen production.

Our technologies will help companies meet ESG goals for Scope 1 and Scope 2 greenhouse gas emissions.

Our Company

RedShift Energy, Inc., a privately held corporation, is developing an innovative plasma chemistry process that safely and effectively converts an unwanted byproduct of the oil industry, hydrogen sulfide (H2S) into two commercial products – hydrogen and sulfur, without carbon emissions.

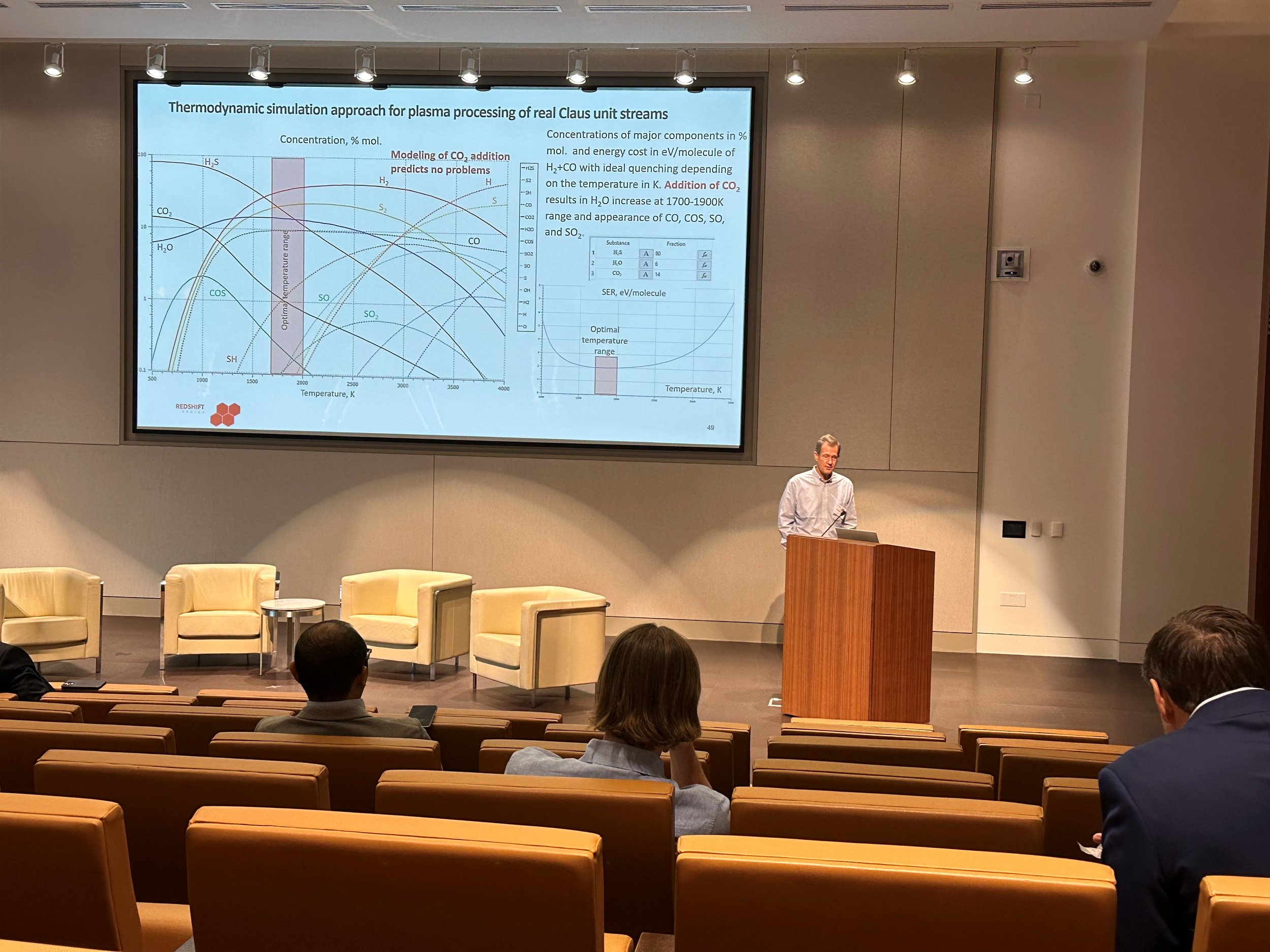

PLASMA CHEMISTRY

Plasma is one of the four major states of matter. There is not a sharp boundary between gas and plasma: gas that contains positively and negatively charged particles, ions and electrons, and therefore is electrically conductive, is plasma. When we control properties of gas with electro-magnetic fields, we work with plasma. Using electricity, it is possible to create plasma with very different properties: for example, hot plasma of electric arc used for welding and cold plasma in fluorescent lamps. Plasma can be used for control of chemical processes.

ENVIRONMENTAL IMPACT

Replacing a Claus-based Sulfur Recovery System (SRS) with RedShift technology, when paired with a renewable source of electricity, will yield zero-carbon hydrogen.

When deployed upstream, the technology helps reduce greenhouse gas emissions by enabling the safe recovery of associated gases.

Clean Hydrogen from H2S

Today, refineries consume 35% of the hydrogen produced worldwide, primarily to remove sulfur from oil products. The oil desulfurization process converts sulfur-containing substances and hydrogen to hydrogen sulfide. Then, hydrogen sulfide is partially oxidized in the Claus process-based sulfur recovery units to sulfur and water vapor. RedShift technology enables the recovery of carbon-free hydrogen from H2S, that is thermodynamically the least expensive source of hydrogen.

Hydrogen Opportunity

RedShift technology is a proprietary method that builds on forty years of research and development. The systems are modular and scalable. It is economically viable from wellhead to refinery scale. A clear opportunity exists for the introduction of this disruptive technology that can economically process H2S. Recovery of carbon-free hydrogen from H2S will result in significant reduction of Scope 1 and Scope 2 greenhouse gas emissions during hydrogen production by steam reforming of hydrocarbons.

Catalyst Free Dry Reforming to Produce Soot-Free Syngas

Using CO2 and methane feedstocks, our proprietary arc plasmatron and gas management system is intended to produce syngas (CO +H2) efficiently and economically. Syngas can be produced in ratios between 1:1 and 3:1 to meet customer product requirements, such as SAF or lubricants. These modular systems will be able to scale in concert with customer strategic goals.

Innovation

Patented Plasmatron

RedShift technology uses a proprietary arc plasmatron to create a high-temperature zone that dissociates hydrogen sulfide and enables hydrogen recovery at atomospheric pressure. The technology is very compact in comparison to the Claus system in a sulfur recovery unit.

Stable Operation

Stable long-term energy efficient operation is enabled by precisely arranged gaseous dynamics and plasmatron materials.

We identified materials that enable electric arc electrodes to operate for extended periods in H2S atmosphere.

Special Flow Dynamics

We are the experts in the formation of electric discharges in vortex flows at atmospheric pressure. Our process enables a shift of the chemical equilibrium of hydrogen sulfide disassociation and an increase in process efficiency.

Downstream Impact

RedShift technology allows recovery and recycling of hydrogen at a cost less than US $1/kg.

This process produces carbon-free hydrogen.

The process has a modular design for maximum operational efficiency and a small footprint.

Upstream Impact

High sulfur content prevents development of many reserves.

Our technology allows for handling of hydrogen sulfide on-site and enables development of high sulfur content reserves.

EVENTS

EVENTS

June 2022

Venue

Houston, TX

Halliburton Labs Selected RedShift Energyfor Industrial Scaling Accelerator

RedShift Energy, Inc. is one of three companies selected by Halliburton Labs to participate in their clean energy accelerator over the next year, starting in June 2022. The RSE team has access to Halliburton's extensive global facilities and resources including engineering services, supply chain, and consulting to further scale and optimize RedShift's novel hydrogen production technology.

23rd World Petroleum Congress

RedShift Energy, Inc. was selected as one of the finalists for the Conoco Phillips Innovation Zone at the 23rd World Petroleum Congress. Innovation was the theme of the Congress, with companies representing over 70 countries in attendance. The Congress is held in cities all over the world, once every three years. It is the first time the Congress was hosted in the United States in over thirty years. Dr. Alexander Gutsol and Howard Nelson introduced the technology to the attendees at the Congress on Monday, December 6, 2021.

March 7, 2023

Venue

Rice Alliance Energy Venture Day

Rice Alliance Energy Venture Day

RedShift Energy, Inc. participated in the Rice Alliance Energy Venture Day at the Rice Business - Jones Graduate School of Business. Howard Nelson, Trey Anthony and Sherry Naismith met with 8 investor groups over a two-hour time period. The meetings provided valuable time to introduce our zero-carbon hydrogen production process and plans to scale up the technology. Howard Nelson presented the novel hydrogen process and plans to scale up to the larger community of corporate venture and investor groups in the pitch competition that followed.

March 8, 2023

Venue

Houston, TX

CERAWeek 2023

RedShift Energy, Inc. participated in the Innovation Agora at CERAWeek 2023. The Houston Energy Transition Initiative (HETI) selected RedShift Energy to present the novel hydrogen production technology in the pitch competition. RedShift Energy was selected as Fan Favorite for their division (pre-seed/Series A) and as Chevron Choice for Catalyst Opportunity, which provides the valuable opportunity to participate in the Chevron Technology Ventures Catalyst accelerator program.

December 5-9, 2021

Venue

Houston, TX

Meet the Team

-

Howard Nelson

Chairman of the Board & CEO

-

Eric Anthony, JD

Counsel

-

Alexander Gutsol, Ph.D.

Chief Science Officer

-

Trey Anthony

Business Development

-

Yuriy Mirochnik

Chief Engineer